DuPont Technology in Your Turnout Gear

When it comes to turnout gear, what’s inside matters most.

Turnout gear made with DuPont technologies combines the proven thermal protection of DuPont™ Nomex® brand fiber with the durability and toughness of DuPont™ Kevlar®, the fiber that’s five times stronger than steel on an equal-weight basis. Nomex® and Kevlar® provide optimum protection against intense heat and flame for gear that is tough and durable, yet comfortable and breathable to help guard against fatigue and heat stress. It all adds up to giving your team the flexibility to work a vehicle accident, ventilate a roof or drag a hose line, and the protection to fight a three-alarm blaze.

The inside story

Over 70% of your turnout gear is made with DuPont™ Nomex® and Kevlar®. Together, they work hard to help keep your professionals safe, inside and out. Helping to protect them against burn injuries from high temperatures, compression, contact, and even flashover conditions. And helping provide outstanding total heat loss (THL) and excellent T6PP. You can rest assured that our scientists and engineers have paid attention to every detail.

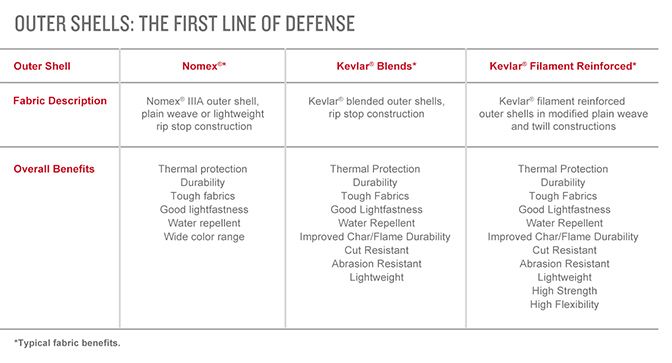

The outer shell

Outer shells constructed with Nomex® and Kevlar® fibers and filament yarns are engineered together to form materials that stand up to heat, stay strong, and protect the inner components and—something more important—you. Kevlar® filament is used in premium fabrics to reduce fabric profile while achieving higher strength and improved flame durability. Durable DuPont™ Teflon® HT treatments keep the gear dry and light and help prevent water from compromising valuable air layers that provide the bulk of the garments’ thermal insulation. That means your professionals have a turnout coat that’s tough and flame-resistant on the outside to help keep what’s inside safe.

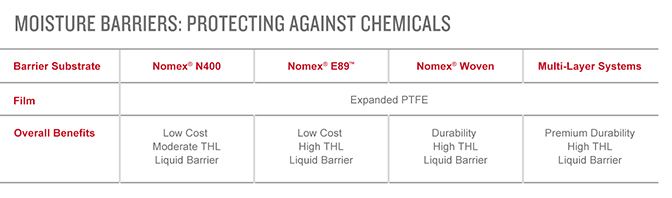

The moisture barrier

Moisture barriers made with Nomex® fabrics, Nomex® E89™ and other nonwovens are proven under real-world conditions and rigorous testing standards, making them the choice of trusted manufacturers everywhere. They provide strong flame-resistant substrates for liquid-impermeable films. The moisture barrier helps protect against the intrusion of water, chemicals and viral agents. Yet these barriers are also lightweight and comfortable to help reduce overall heat stress during strenuous activities. All to help your professionals stay drier, more ergonomic and ready for even the most difficult situations.

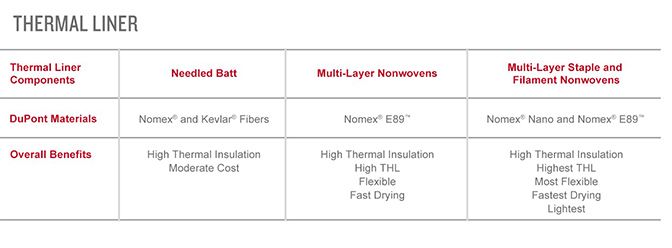

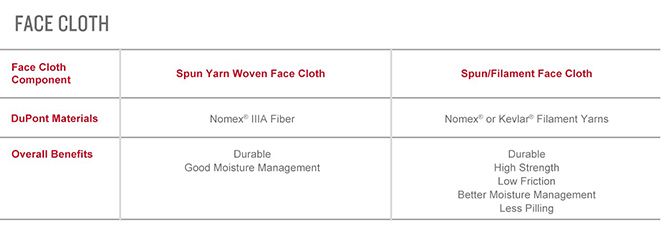

The thermal liner

Thermal liners provide the majority of your turnout system’s thermal protection. Nomex® and Kevlar® fiber batts and Nomex® E89™ nonwovens, combined with Nomex® and Kevlar® fiber and filament face cloths, provide durable, flexible, heat-insulating components. Multilayer Nomex® E89™ based thermal liners, especially when combined with Nomex® Nano, are among the thinnest, most flexible and breathable available. Face cloths with Nomex® and Kevlar® filaments help reduce surface friction, improving overall garment mobility. Liner water-wicking or repellent finishes improve comfort and moisture management and reduce drying time. The thermal liner is protection where it matters most, and it’s good to know DuPont™ Nomex® and Kevlar® are there when it matters most.

The first choice for all your protection needs

Whether your priority is thermal protection, durability, mobility, comfort or decreased bulk, DuPont is committed to delivering an entire system designed to meet your exact performance requirements. DuPont materials also help protect professionals even when the fire is out. Stationwear made with Nomex® is durable, comfortable and NFPA 1975 compliant. DuPont™ Tychem® chemical protective garments are helping keep first responders safe. And hazmat teams turn to DuPont™ Tychem® 6000 FR for a single-layer garment that helps protect against the triple threat of flash fires, chemicals and electric arc.

DuPont materials have been a leading choice in the fire service market for more than 40 years. It all began with the material firefighters ask for by name, DuPont™ Nomex®. But the innovation continues. Our scientists and engineers participate in committees like the NFPA to help create the standards. We’re also developing new solutions like Nomex® On Demand™ that automatically activates at 250 degrees Fahrenheit to give you increased thermal performance when you need it most. During routine conditions, it remains thin, breathable and flexible for exceptional mobility.